EnviroTemp® Eliminates Oil Fouling in HVAC+R

Improves COP and Delta T of all types of HVAC+R equipment through thermodynamic metal enhancement.

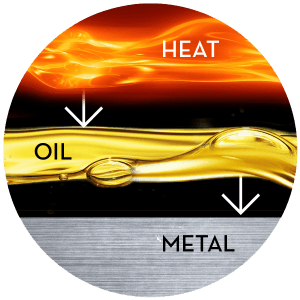

Oil sticks to metal surfaces

Oil blocks heat from moving through metal

SOLUTION: Remove the oil.

NO ENERGY LOSS

Move heat more effectively

MACHINE RUNS LESS, OPERATIONAL COSTS REDUCED

What EnviroTemp Does

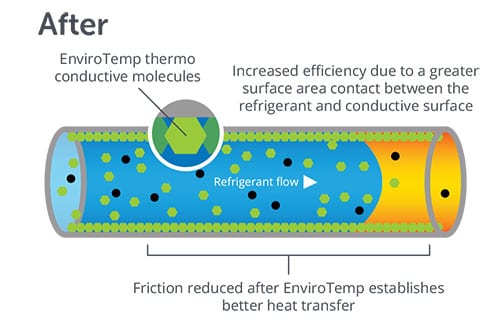

Increase the thermo-conductive properties of the coil system through nano-magnetic filming and electron transfer enhancement

Regain the lost efficiency caused by oil migration by displacing the barrier of conductive oil

Allows the HVAC+R unit to move more heat, reaching the thermostat set-point faster, run less and consume less kWh.

EnviroTemp is currently saving energy in over 130,000+ installations worldwide

Regain and prevent lost cooling capacity | Reduce kWh consumption | Extend the life of HVAC+R equipment

%

Laboratory and field verified

%

kWh energy reduction with EnviroTemp

%

Increased equipment life from reduced HVAC+R runtime

* Results may vary depending on application

Payback is 24 months or less

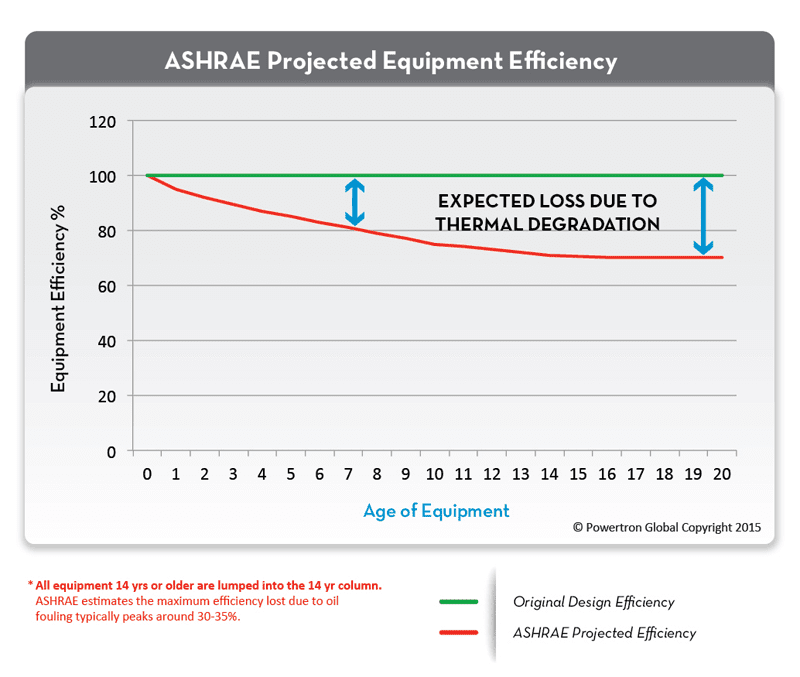

EnviroTemp is a patented product, installed successfully in thousands of installations worldwide. The technology is scientifically proven, has long term customer history and is verified by recognised third parties. However, don’t just take our word for it, below see what A.S.H.R.A.E, a world leading authority on HVAC+R equipment has to say about the problem of oil fouling.

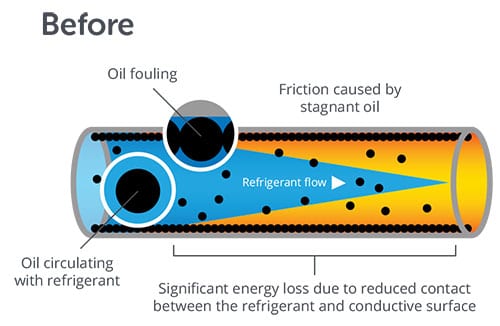

A.S.H.R.A.E (American Society of Heating, Refrigeration and Air-Conditioning Engineers) has studied the problem of oil fouling. A.S.H.R.A.E estimates that this thermal barrier accounts for up to a 30% reduction in efficiency within the first 5 years of the equipment life.As studied by A.S.H.R.A.E, during the refrigerant compression process, oil migrates from the compressor to the coil system contaminating the metals that transfer heat. Compressors that use oil for lubrication do not prevent oil from fouling the coil system. Even the smallest amount of oil in the coil system creates a film or coating that will hinder heat transfer reducing the efficiency of the unit.gs.

EnviroTemp is a High Value Energy Conservation Measure

- Unmatched in terms of financial return

- For most installations the decrease in kWh consumption equates to between 10% and 15% power bill savings

- Installation is simple and will not interrupt your business during roll-out.

- Equipment runs less and lasts longer. Extend the life of your HVAC+R assets.

What is EnviroTemp? Why is it called a "Surface Science" and not an Oil Additive?

Though EnviroTemp is installed into the suction side of any climate control system, EnviroTemp is categorised as surface science thermal technology, not an oil or refrigerant additive. Unlike those types of products, at no time in the ECM (energy conservation measure) process does EnviroTemp materially mix with, alter or chemically affect the viscosity, flashpoint or pour point of the refrigerant oil in the equipment. The same is true for the refrigerant. It is also important to understand that EnviroTemp is not a detergent or a solvent. EnviroTemp simply uses the refrigerant as a transport mechanism to carry it throughout the system during the gestation period.

Once injected inside a system, EnviroTemp immediately becomes attracted to all metal surfaces, embedding itself into the microscopic crystal lattice and taking itself out of active circulation. This chemical process is actually one of displacement, in that EnviroTemp replaces the refrigerant oil impinged within the crystal lattice of the heat exchanger(s) and all metal surfaces which is known as oil fouling. This displacement action then produces a Nucleo Molecular Regenerative (NMR) impingement of the crystal lattice surface resulting in superior heat energy transfer. Working together, these actions result in energy savings measured at the equipment level of 10-30%, thus producing a Return on Investment (ROI) in months instead of years.

The displacement of the oil fouling within any climate control system happens slowly over several weeks. After the initial oil fouling is removed from the crystal lattice, the combination of the EnviroTemp treated surfaces and refrigerant flowing across those surfaces, prevents oil fouling from ever reoccurring. This newly treated crystal lattice surface also allows metal to transfer heat more efficiently. Heat is one of the primary causes of metal degradation, which can lead to catastrophic failures.

Inside the compressor, EnviroTemp will not, in any way, impede the design specifications of the instantaneous oiling system. The compressor’s oil will still adhere to the treated surfaces long enough to provide the needed mechanical lubrication. The appearance is that EnviroTemp enhances the lubrication properties of the oil. In actuality, it’s the surface heat transfer abilities of the metal that have been changed. This allows the oil to provide even more effective lubrication because there is less surface heat energy within the mechanical friction to overcome.

What are the main benefits of EnviroTemp?

Removing oil fouling from the heat exchange surfaces allowing the system to reach set temperatures quicker, which in turn enables the HVAC+R system to shut off or unload for longer periods. The benefits include:

· A reduction of 10-30% in energy consumption directly at the unit

· An improvement in the thermal heat energy transfer ability of the overall system

· The restoration of system capacity and COP lost over time

· A slight reduction in Amp draw due to reduction of mechanical heat energy

Will EnviroTemp negatively affect my HVAC+R equipment warranty?

No. EnviroTemp is NOT an oil additive. It DOES NOT affect the viscosity, flashpoint, pour point or any other characteristics of the equipment refrigeration oil or the refrigerant. This greatly concerns manufacturers. Large sums of money are expended in the development of lubricants to be utilised for their equipment. Their initial assumption is that we are adding something to the chemistry of the lubricant. We are not. EnviroTemp simply and temporarily uses the refrigerant only as a transport mechanism to allow it to be circulated throughout the system heat transfer surfaces.

Does EnviroTemp come with any equipment warranty?

Yes. With the installation of EnviroTemp up to $1,000,000 of liability coverage for every HVAC+R system is provided. As part of this warranty, coverage is also provided for any potential loss of revenue or products for up to $2,000,000 that results from a HVAC+R system outage directly attributable to EnviroTemp. Coverage duration is for the remaining life of the warranted equipment. Detailed information regarding this terms of the warranty are available on request.

In more than 130,000 installations there has never been a liability claim against the product.

How long does the product take to install?

The product takes less than 30 minutes to install in most HVAC+R systems, which includes the time necessary for ensuring the system being treated is in good operating condition. The installation also requires no down-time of the equipment so there is no interruption to a customer’s normal business operations.

Are there any special handling requirements for EnviroTemp?

No. The product is totally safe for both humans and the environment. A MSDS is available upon request.

If my system has a separator, do I still need EnviroTemp?

A separator is a device that attempts to remove oil from refrigerant. This device does separate a majority of the oil out of the refrigerant, but not all of it. Even if you have a separator, EnviroTemp will still improve the efficiency of the chiller because it works in the heat exchangers, not in the refrigerant.

Would you like more information about how EnviroTemp can improve the performance of your HVAC+R equipment? Please feel free to contact us and one of our team will answer any questions you may have.

Phone: 1300 782 761

sales@promektechnologies.com.au

www.promektechnologies.com.au

Promek Technologies Pty Ltd

Building No. 5

49 Frenchs Forest Road

Frenchs Forest NSW 2086

ABN 39 150 627 535