Advanced Control Technology that Optimises HVAC+R

Optimises compressor run time

COOLNOMIX® Is a smart refrigeration and air-conditioning control. By optimising run time of compressor saves energy. COOLNOMIX® uses ORS technology which uses two sensors continually reads supply and space temperature allowing for maximum efficiency in compressor run time. ORS technology also utilises off cycle dormant refrigerant in evaporator which means free cooling in the off cycle.

Each air-conditioner (or refrigeration) unit has a maximum design capacity – the maximum temperature at which it can operate effectively and maintain a desired set-point. In these conditions, the compressor runs continuously. When the conditions are milder, the compressor is controlled by the thermostat using a crude control logic: if temperature 1°C above set point go ON, if the temperature 1°C below set point go OFF. The time it takes to lower the temperature to the thermostat by 2°C depends on the compressor’s ability to supply refrigerant as a minimum, but also the load, ventilation, sensor placement etc.

All COOLNOMIX® products make use of a unique, patented advanced control technology called Optimised Refrigerant Supply (ORS™).

This COOLNOMIX® ORS™ technology uses two temperature sensors in an algorithmic energy trading control arrangement to monitor the thermodynamic (room or space temperature) and the hydraulic (refrigerant supply) performance of the connected air conditioning, heating or refrigeration system.

COOLNOMIX® is a winner of the prestigious Green Innovations Award from the Hong Kong Environmental Campaign Committee.

The Green Innovations Award recognises demonstrated innovation in the field of energy conservation.

In addition to this prestigious award COOLNOMIX® is the recipient of numerous other awards and recognition from environmental and energy management authorities

Used by some of the worlds leading companies

Delivering unrivalled energy savings on HVAC equipment

COOLNOMIX®’s secret weapon is ORS®, a patented algorithmic energy optimisation control methodology, which stands for Optimised Refrigerant Supply. Together with two temperature sensors, it monitors the thermodynamic (room temperature) and the hydraulic (refrigerant supply) performance of the air conditioning system to eliminate periods of unnecessary work.

In practice, ORS®’ first priority is to ensure the desired setpoint has been achieved using its return air sensor. It then uses its return and supply air sensors together to determine whether spare cooling capacity is available in the evaporator and stops the compressor until the unit ceases cooling. Consequently, when the compressor restarts, the condenser is relatively cool and at low pressure, while the evaporator is relatively warm and full of vapour, giving the compressor the most ideal conditions in which to operate efficiently.

Lets look at a real life example

Take a unit with the capacity to maintain a set point of 23°C on a 35°C day as an example. The thermostat starts the compressor at 24°C and stops it at 22°C. Today the temperature is only 27°C, and it takes 10 minutes for enough air to flow across the evaporator to reduce the temperature by that 2°C. But in today’s conditions, the compressor only needs seven (7) minutes to compress and liquefy the required amount of refrigerant. During the extra 3 minutes it tries to draw vapour that is not readily available from the evaporator, and tries to ram it into an already highly-pressurised condenser. The compressor is working hard but achieving little more than over-heating the condenser. This is the inefficiency COOLNOMIX® addresses.

Overall, the benefits delivered by our COOLNOMIX® ORS™ algorithmic energy trading control system include:

- Unrivaled energy-saving performance compared with the best modern inverter systems

- Improved temperature stability and comfort assurance

- Improved air quality with reduced carbon footprints

- Zero dripping or icing up, thereby eliminating any need for heating equipment – even with COOLNOMIX® ORS™ refrigeration control systems

- Improved performance and reliability (backed up by a three-year warranty on all COOLNOMIX® ORS™ control systems).

Payback in less than 2 years

%

Energy Savings

Frequently Asked Questions

How can COOLNOMIX deliver such large energy savings?

COOLNOMIX® optimises the operational run-time of the cooling system compressor. Since the compressor accounts for ~95% of the power consumption of a cooling system, optimising its run-time can deliver very large savings.

COOLNOMIX® employs two temperature sensors – one to regulate the room/space temperature delivered, the other to measure the cold-supply air temperature. The latter is used to determine when the hydraulic work of the compressor is completed – when the refrigerant gas is fully compressed. Once this reservoir of cold-supply has been created, COOLNOMIX® stops (non-inverter) or slows down (inverter) the compressor until further hydraulic work is needed. It is the compressor off-time or slowed-time that delivers the astonishing energy savings.

What factors determine whether COOLNOMIX saves 15% or 40% in energy?

- a well maintained system, with the right refrigerant levels, clean filters and a healthy compressor are a must. It need not be new, but it must work properly

- the larger the room being cooled, the better the savings

- the lower the heat load in the room, the better the savings

- the more effective the condenser (better able to remove heat), the better the savings

- relative to a perfectly sized system, if the system is undersized, savings will be less (or non-existent), if the system is oversized, savings will be more

Doesn't the increased stop-start process introduced by COOLNOMIX damage the compressor?

The internationally patented process Optimised Refrigerant Supply (ORS®) which is incorporated in COOLNOMIX® has specific protection included within its function. This includes protection against too frequent stop-start of the compressor and assurance that every re-start is always a soft-start – the re-start of the compressor is never under load since the suction and discharge pressures are guaranteed to be in equilibrium. As a result there is no adverse effect on the operational life of the compressor of the cooling system.

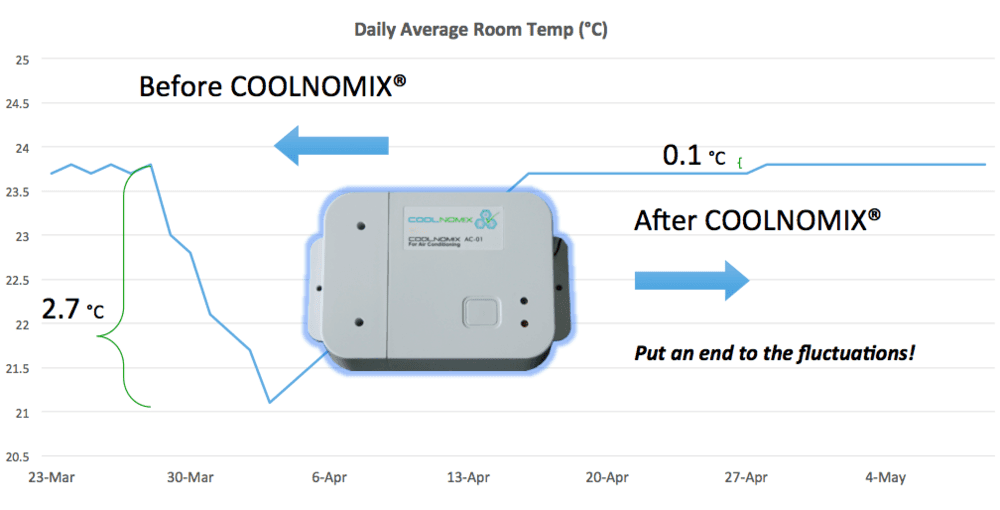

What about temperature stability when using COOLNOMIX?

ORS® incorporates a priority on delivering the required room/space temperature – energy savings will be sacrificed in order to ensure the room/space temperature is achieved. COOLNOMIX® typically improves temperature control in air-conditioning and refrigeration systems. In contrast with most installations having room/space temperature variations of 1-2°C, our dual temperature sensor approach commonly limits room temperature variations to 50% of that experienced without COOLNOMIX®.

If we achieve the same amount of thermodynamic work, shouldn't we be using the same amount of mechanical work?

No we don’t. The best way to explain that is to use a car analogy. If you go from A to B, petrol consumption does vary depending on the load. You will, for example, use more petrol on the trip, all else being equal, if you drive faster, fully loaded, with the hand break on, uphill, with flat tyres, or roof racks etc. COOLNOMIX® runs the compressor most efficiently, getting from A to B for minimal energy.

Isn't the warranty of the cooling system invalidated by retrofitting COOLNOMIX?

No it should not, but we cannot review the warranty terms of every air-conditioner on the market.

Air conditioners have expected lifetimes of 15 to 20 years; consequently, the vast majority are not under warranty. For those units that are, COOLNOMIX® is merely an intelligent thermostat, which does not interfere with the cooling system, the compressor, the refrigerant or the control boards – all operate as normal.

If COOLNOMIX® was to void a warranty, it would mean all third party thermostats would too.

On what cooling systems can COOLNOMIX be deployed?

COOLNOMIX® can be retrofitted to all refrigerant based commercial air conditioning installations controlled by a single thermostat and designed to work at fixed set-point temperatures. Provided the unit is well maintained and appropriately sized, COOLNOMIX® works with all of the following:

- Split (wall or cassette) / Packaged / Split Ducted

- VRV / VRF / Inverter; Single phase or three phase

- Cool only or reverse cycle (no savings in heat mode)

- Single-stage or dual-stage

- Air cooled or water cooled condensers

Note: COOLNOMIX® is not currently suitable for central chilled water systems (large office buildings, hotels, shopping centres) or evaporative coolers

How hard is it to install?

COOLNOMIX® must be installed by a qualified technician. However the installation is relatively simple: it involves installing two temperature sensors and a control connection in line with the existing thermostat. In most cases, your HVAC technician will take less than an hour to do it.

What is ORS?

Optimised Refrigerant Supply (ORS) is a unique and patented advanced control technology invented by the developers of the Coolnomix device, Agile8 Consulting Ltd, a Hong Kong based technology company. ORS delivers the optimal balance between energy consumption and the supply of refrigerant required to achieve the desired comfort level.

What is the COOLNOMIX third generation technology?

There are other “compressor optimisation” technologies on the market, some more successful than others.

First generation products saved energy by attempting, through timers or other means, to reduce the compressor ON time by arriving at an ‘Optimal’ mark-space ratio between compressor ON and OFF times. These devices have no concept of a temperature set point and only deliver savings under medium load and medium humidity conditions but hit problems with temperature stability under more demanding circumstances.

Second generation products attempted to satisfy set point objectives, but with limited timer based and/or single temperature sensor resources.

COOLNOMIX® is a third generation energy saving technology as it makes use a 2 temperature sensors and has algorithms that are optimised to each of the 16 temperature settings within.

Is COOLNOMIX truly unique?

The obvious question that springs to mind is “why isn’t every air conditioner doing this already?”. There is a two part answer to that question.

The first part is market driven. Commercial air-conditioners and refrigerators must be able to interface with a range of third party controllers, BMS and/or thermostats, and generally do not integrate dynamic control features – they bring the muscle not the brain.

The second part of the answer is that it just isn’t that simple. COOLNOMIX® is a third generation product, and while others have tried to improve efficiency by using compressor cycling or PID controls, none before COOLNOMIX® have used a dynamic two sensor method.

Would you like more information about how COOLNOMIX can improve the performance of your air cooled HVAC+R equipment? Please feel free to contact us and one of our team will answer any questions you may have.

Phone: 1300 782 761

sales@promektechnologies.com.au

www.promektechnologies.com.au

Promek Technologies Pty Ltd

Building No. 5

49 Frenchs Forest Road

Frenchs Forest NSW 2086

ABN 39 150 627 535